How the drum brake works

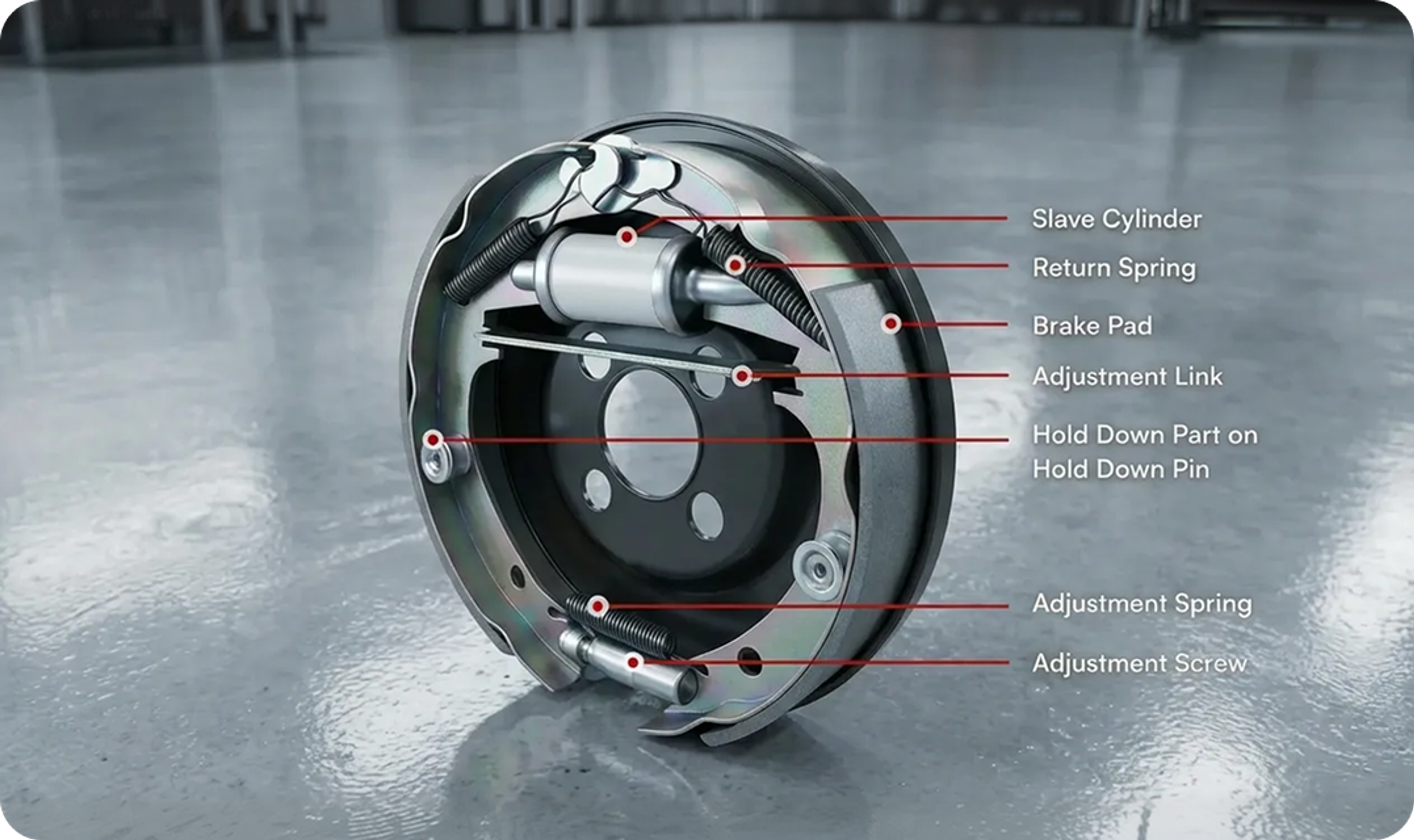

structure

In a drum brake, the brake drum rotates with the wheel. Inside the drum are two brake shoes that are operated by a wheel brake cylinder or a mechanical lever. When the brake pedal is pressed, the master brake cylinder transmits hydraulic pressure to the wheel brake cylinder, which pushes the brake shoes outward. The brake shoes press against the inside of the brake drum, creating friction that slows down the wheel. Thanks to the closed system, brake dust and dirt are less likely to accumulate.

Heat generation and cooling

The friction between the brake shoes and the brake drum converts kinetic energy into heat. Unlike disc brakes, the heat generated by drum brakes is mainly stored inside the drum and released more slowly into the environment. Although the closed design protects against external influences, it also makes cooling more difficult. Under heavy loads, this can lead to thermal fading more quickly. However, modern drum systems are designed to operate reliably under normal conditions.

Effects on braking performance

Drum brakes respond gently and are efficient thanks to the self-reinforcing effect of the brake shoes. They are well suited for smooth braking, especially at lower speeds. Their enclosed design makes them less sensitive to water, dirt, and corrosion. However, the overall braking performance of a vehicle is more strongly influenced by the front disc brakes. Drum brakes play an important role in modern braking systems, primarily as parking brakes and as additional braking components on the rear axle.

Advantages of drum brakes

- Robust construction: well protected against dirt and moisture

- Lower costs: both in manufacturing and in the spare parts sector

- Long service life: the internal components are protected from external influences

- Good parking brake: Drum systems are ideal for use as parking brakes.

- Self-reinforcement: reduced pedal pressure due to the design of the brake shoes

Disadvantages of drum brakes

- Limited heat dissipation: under heavy continuous load, they can overheat more quickly

- More complex maintenance: the drum must be removedin order to replace the brake shoes.

- Less controllable: less precise than disc brakes

- Uneven wear: Adjustment may be necessary to ensure even braking performance.

Areas of application for our products

Today, drum brakes are mainly used on the rear axles of smaller passenger cars, commercial vehicles, and trailers. There, they ensure stable braking performance and support the parking brake. The drum brake system consists of the following components:

- Brake shoes: generate braking force through friction on the brake drum

- Brake drums: rotating friction surface and protective housing

The Danaher catalog contains suitable brake shoes, brake drums, and complete installation kits designed for different vehicle types and operating conditions.

product features

OE specifications

Our drums meet original equipment (OE) specifications, ensuring compatibility and reliability.

High-quality materials

Our products are made from high-quality materials and undergo rigorous testing. The simplex design ensures quiet operation and long-lasting quality.

rust resistance

Our coating provides excellent corrosion protection and outperforms conventional paint or zinc coatings.

Easy installation

Danaher products are precisely matched to a wide range of vehicle makes and models, ensuring easy installation and optimal braking performance.

Now rely on tested drum brakes

Benefit from precisely fitting components, durable materials, and reliable braking performance.

Maintenance and typical problems

Signs of wear and noise

Worn brake shoes often make themselves noticeable through squeaking or grinding noises. Longer pedal travel or uneven braking can also indicate wear. Dirt or rust in the drum can cause noise, so the drum system should be cleaned and inspected regularly.

Maintenance of brake drums

A pulsating brake pedal can indicate a warped or unevenly worn brake drum. Causes include excessive heat or mechanical damage. Regular inspection of brake shoes, drums, and the associated springs helps to identify problems at an early stage. Drum brakes sometimes need to be readjusted to ensure even braking.

Why are Danaher brake components a reliable choice?

Reliable quality and durability

Through defined quality checks and high-quality materials, Danaher products guarantee long-lasting, reliable performance.

High safety standards

Exact fit and precise friction materials support stable and controllable braking performance even with long maintenance intervals.

Precise fit for many vehicle types

The range is designed to cover a wide selection of brands and models. This ensures problem-free installation and even wear of the brake components.

FAQs about our brake drums

Our brake components are designed for easy installation. However, we recommend that they be installed by a professional mechanic to ensure correct adjustment and optimum safety.